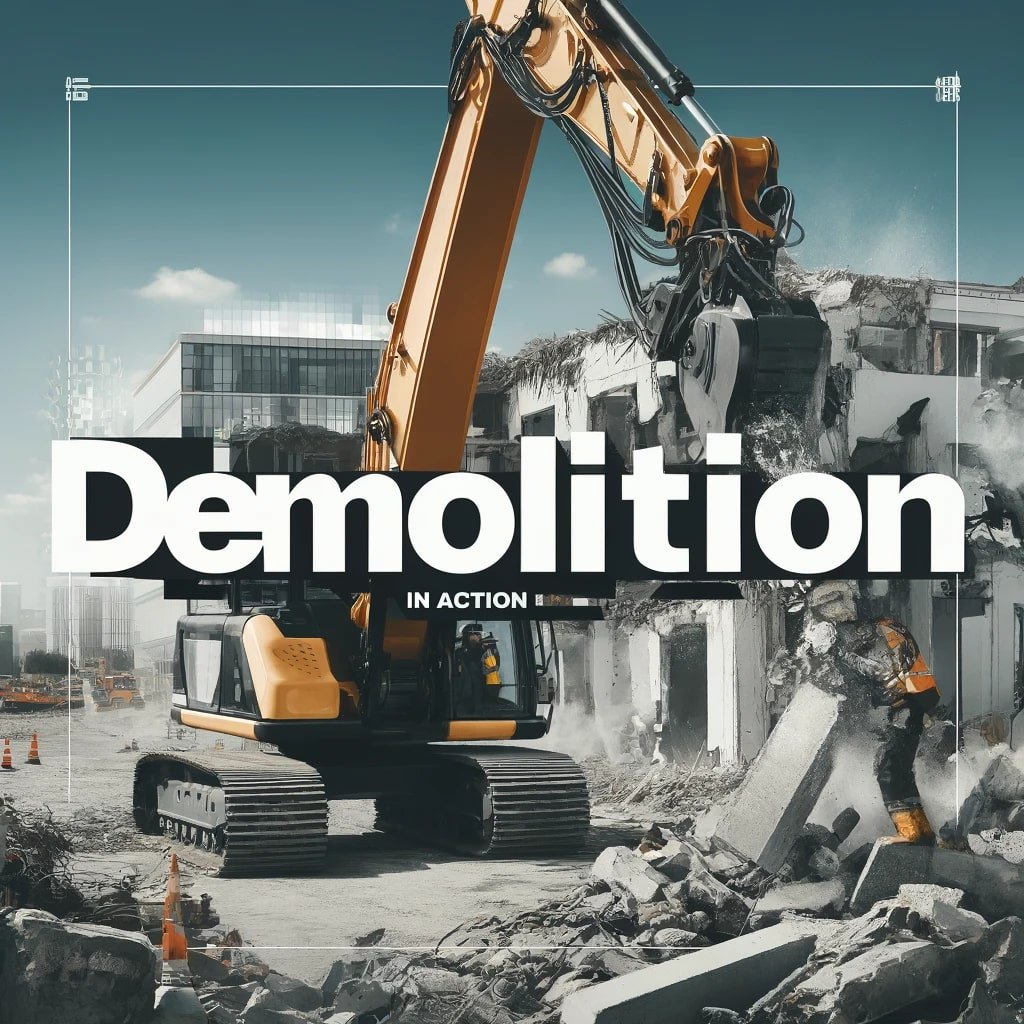

Demolition projects require specialized equipment to efficiently and safely dismantle structures. Excavators are among the most versatile and powerful machines used in these projects. Here, we explore the different types of excavators commonly employed in demolition and their specific uses.

1. Standard Excavators

Overview: Standard excavators are the most common type of excavator, featuring a boom, dipper, and bucket attached to a rotating cab on tracks or wheels.

Uses in Demolition:

-

Versatility: Ideal for various demolition tasks, from breaking down walls to lifting debris.

-

Attachments: Can be equipped with different attachments like hydraulic breakers, shears, and grapples for specific demolition activities.

Advantages:

-

Adaptability: Can handle a wide range of tasks with the right attachments.

-

Powerful: Strong enough to manage large demolition projects.

2. Long Reach Excavators

Overview: Long reach excavators have extended booms and arms, allowing them to reach higher and farther than standard models.

Uses in Demolition:

-

High-Reach Demolition: Perfect for demolishing tall buildings or structures from the top down.

-

Remote Operation: Can work from a safe distance, minimizing risk to operators.

Advantages:

-

Extended Reach: Can reach heights and distances that standard excavators cannot.

-

Safety: Allows for safer demolition of tall structures.

3. Mini Excavators

Overview: Mini excavators are compact and lightweight, making them ideal for small-scale demolition projects and confined spaces.

Uses in Demolition:

-

Interior Demolition: Suitable for indoor demolition tasks where space is limited.

-

Precision Work: Ideal for tasks requiring precision, such as removing small sections of walls or floors.

Advantages:

-

Maneuverability: Can navigate tight spaces and access areas that larger machines cannot.

-

Less Damage: Minimizes damage to surrounding structures due to their smaller size and precision.

4. Hydraulic Excavators

Overview: Hydraulic excavators use hydraulic fluid power to perform various demolition tasks.

Uses in Demolition:

-

Heavy-Duty Demolition: Capable of breaking through concrete and steel structures.

-

Attachment Compatibility: Can be fitted with a variety of hydraulic attachments like breakers, crushers, and pulverizers.

Advantages:

-

Powerful: Offers significant force and precision for heavy-duty demolition.

-

Efficiency: Can perform multiple tasks with different hydraulic attachments.

5. Crawler Excavators

Overview: Crawler excavators are mounted on tracks rather than wheels, providing better stability and traction.

Uses in Demolition:

-

Uneven Terrain: Suitable for demolition sites with rough or uneven ground.

-

Heavy Lifting: Ideal for lifting and moving large debris and heavy materials.

Advantages:

-

Stability: Tracks provide excellent stability, even on uneven surfaces.

-

Durability: Designed to handle challenging demolition environments.

6. Wheeled Excavators

Overview: Wheeled excavators are similar to crawler excavators but are mounted on wheels, providing greater mobility on paved surfaces.

Uses in Demolition:

-

Urban Demolition: Ideal for demolition projects in urban settings with paved roads and limited space.

-

Quick Relocation: Can move quickly between different parts of the site or between sites.

Advantages:

-

Mobility: Faster and more efficient movement on paved surfaces.

-

Versatility: Can be used for a variety of tasks with different attachments.

Conclusion

Choosing the right type of excavator for demolition depends on the specific needs of the project. Standard excavators offer versatility, while long reach and mini excavators provide solutions for high-reach and confined-space demolition. Hydraulic, crawler, and wheeled excavators each have unique benefits that make them suitable for different demolition environments. Understanding the capabilities and advantages of each type of excavator ensures that demolition projects are carried out safely, efficiently, and effectively.

Deconstructors demolition .inc 2024-05-24