When people hear the term “sealed asbestos containment zone,” they often imagine something dramatic. Plastic walls. Warning signs. Workers in full protective suits imagining danger at every step. While some of that imagery is accurate, most people do not understand what is really happening once a containment zone is sealed and work begins.

The purpose of a containment zone is not just to remove asbestos. It is to control air, movement, and exposure in a way that keeps everyone outside the work area safe. Inside the zone, every step follows a strict process designed to manage microscopic fibers that cannot be seen or smelled but can cause serious harm if released.

For property owners in Edmonton, understanding what actually happens inside a containment zone helps remove fear and confusion around asbestos work. Asbestos abatement Edmonton projects rely on is not guesswork. It is a carefully controlled environment built around air management, discipline, and precision.

WHY CONTAINMENT ZONES EXIST IN THE FIRST PLACE

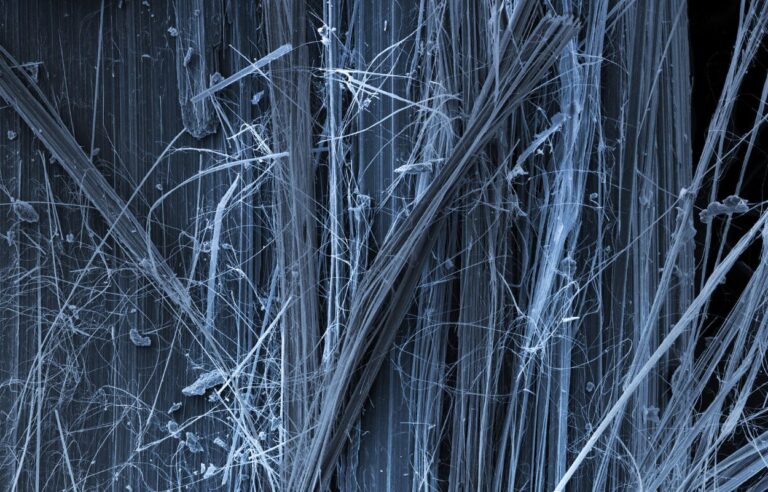

Asbestos becomes dangerous when its fibers are released into the air. These fibers are incredibly small and can remain airborne for long periods of time. Once inhaled, they can lodge deep in the lungs and cause serious health issues years later. Containment zones exist to prevent those fibers from escaping into occupied or public areas.

The goal is not just to protect workers, but also to protect residents, tenants, neighboring spaces, and the building itself. Instead of allowing fibers to spread throughout a structure, containment isolates the work area and keeps contamination controlled. Everything that happens inside the zone is designed to support that single objective.

HOW A CONTAINMENT ZONE IS BUILT

Before any asbestos is touched, the containment zone is constructed. This process is methodical and intentional. Heavy-duty polyethylene sheeting is installed over floors, walls, and ceilings to create an airtight barrier. Seams are sealed carefully. Openings are reinforced. Entry points are designed with multiple layers so nothing passes through without control.

Critical to this setup is negative air pressure. Specialized air filtration machines are installed to pull air inward, not outward. This ensures that if there is any leak, air flows into the zone instead of allowing fibers to escape. Once the containment is sealed and pressure-tested, the space becomes a controlled environment. Only trained workers wearing protective equipment are allowed inside.

WHAT WORKERS WEAR INSIDE THE ZONE

Inside a sealed containment zone, workers wear full personal protective equipment. This typically includes disposable suits, gloves, boot covers, and respirators designed to filter asbestos fibers. This equipment is not optional. It protects workers from inhalation and prevents fibers from being carried out of the zone on clothing or skin.

Every movement inside the containment is deliberate. Workers are trained to avoid unnecessary motion that could disturb materials or create airborne fibers. Even walking patterns are considered as part of contamination control.

HOW AIR IS MANAGED DURING ABATEMENT

Air control is the heart of asbestos abatement. Inside the containment zone, negative air machines continuously pull air through HEPA filters. These filters are designed to capture extremely small particles, including asbestos fibers. The machines run constantly while work is underway. Airflow is monitored to ensure pressure levels remain stable.

If pressure drops or airflow changes, work may stop until the issue is corrected. This constant air movement prevents fibers from lingering and ensures they are captured immediately. It also protects the integrity of the containment by preventing outward airflow.

HOW ASBESTOS MATERIAL IS ACTUALLY REMOVED

Contrary to popular belief, asbestos is not simply ripped out. Materials are often wetted before removal to reduce fiber release. Wetting keeps fibers heavier so they do not become airborne as easily. This step alone dramatically reduces contamination risk. Workers remove materials slowly and carefully. Pieces are handled gently, not broken apart aggressively.

Asbestos waste is placed directly into sealed, labeled bags designed specifically for hazardous material. Nothing is left loose. Nothing is carried openly. Everything follows a strict chain of custody from removal to disposal.

WHAT HAPPENS TO DEBRIS AND TOOLS

Inside the containment zone, debris management is constant. Waste bags are sealed inside the zone before being moved to a designated transfer area. Tools are cleaned regularly. Surfaces are wiped down repeatedly throughout the process, not just at the end.

Nothing leaves the containment without being decontaminated. This includes tools, equipment, and even the workers themselves. This level of discipline is why asbestos abatement Edmonton projects do not rely on shortcuts. One lapse can compromise the entire system.

HOW WORKERS EXIT THE CONTAINMENT ZONE

Exiting the zone is as controlled as entering it. Workers pass through a decontamination sequence that removes fibers from protective gear before they reach clean areas. Disposable equipment is removed in a specific order. Respirators are cleaned or stored properly.

This process prevents fibers from traveling beyond the containment. It also protects workers from carrying contamination home or into vehicles. Decontamination is not rushed. It is treated as a critical part of the job, not an afterthought.

WHAT CLEANING LOOKS LIKE INSIDE THE ZONE

Once asbestos removal is complete, cleaning begins. Every surface inside the containment is cleaned thoroughly. HEPA vacuums are used on walls, floors, ceilings, and structural elements. Wiping and vacuuming may happen multiple times.

This cleaning phase often takes longer than people expect. It is not about appearance. It is about removing microscopic contamination that cannot be seen. Only after cleaning is complete does clearance testing take place.

HOW CLEARANCE TESTING WORKS

Air testing is used to confirm that asbestos fiber levels inside the containment meet safety standards. Samples are taken and analyzed by qualified professionals. If levels are too high, additional cleaning is performed and testing is repeated.

The containment zone is not removed until testing confirms that the area is safe. This step is non-negotiable. Clearance testing provides documentation that the work was done correctly and that the space can be returned to use without risk.

WHY CONTAINMENT IS MORE THAN JUST PLASTIC SHEETS

From the outside, containment zones may look simple. Plastic walls and warning signs do not seem complex. Inside, however, the process is highly technical. Airflow, pressure, material handling, worker movement, and cleaning protocols all work together. If any one part fails, the entire system is compromised. This is why asbestos abatement Edmonton contractors emphasize process over speed. The work must be done correctly, not quickly.

WHAT PROPERTY OWNERS OFTEN MISUNDERSTAND

Many property owners assume asbestos abatement is primarily about removal. In reality, removal is only one part of a much larger system. The real work happens in air control, containment integrity, and procedural discipline. These are the elements that protect occupants, neighboring spaces, and long-term building health. Understanding what happens inside a containment zone helps explain why asbestos work requires time, planning, and professional oversight.

FINAL THOUGHTS

A sealed asbestos containment zone is not a dramatic overreaction. It is a controlled environment designed to manage an invisible hazard safely and responsibly. Inside the zone, every action serves a purpose. Air is controlled. Materials are handled carefully. Workers follow strict procedures. Nothing moves without intention. Asbestos abatement Edmonton property owners rely on is built around this precision. It protects people, preserves buildings, and ensures that asbestos issues are resolved without creating new ones. When done properly, containment is not something to fear. It is the reason asbestos can be removed safely at all.